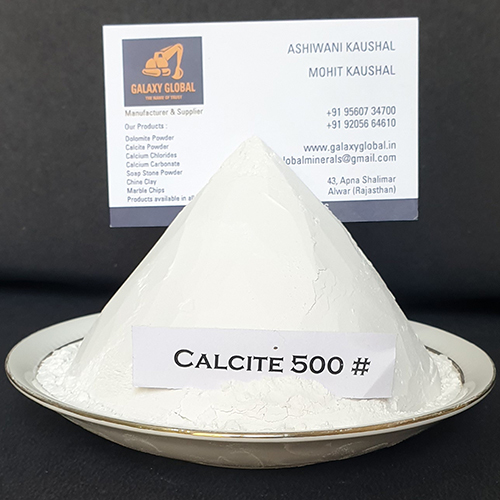

Calcite Powder 500 Mesh

Product Details:

Calcite Powder 500 Mesh Price And Quantity

- 900.00 - 4000.00 INR/Ton

- 5 Ton

Calcite Powder 500 Mesh Trade Information

- 100 Ton Per Month

- 1 Week

Product Description

WHAT IS IT?

Calcite, as the name suggests is a naturally occurring mineral calcium carbonate (CaCO3). Its composition is identical to that of limestone but the latter occurs as sedimentary beds.Calcite is present extensively in Rajasthan, India, where Galaxy Global is located. It is found in veins traversing various rock types particularly within the Aravalli and Ajabgarh series, which are ancient mountain ranges of Rajasthan. Calcite veins 30 to 150 cm thick, running uniformly sometimes for long distances, are usually found. Calcite of very high brightness of upto 99% is found in Rajasthan

MOLECULAR STRUCTURE

Calcite structure is formed by an ionic interaction Ca2+ (calcium cation) and CO32- (carbonate anion). For every one carbonate anion there is one calcium cation, thereby making the structure electrically neutral.

PROPERTIES

Tactile properties: It is rough and abrasive.

Visual properties:

Color: It is white in color but is also found in various shades like pink, brown etc, depending upon the impurities present. Color is white or none, though shades of gray, red, orange, yellow, green, blue, violet, brown, or even black can occur when the mineral is charged with impurities.

Luster: It’s luster is vitreous to pearly on cleavage surfaces in crystallized varieties and vitreous to resinous to dull in massive forms.

Streak: It’s streak is white.

Diaphaneity: It is transparent to opaque.

Structural properties: It has a defining mohs hardness of 3, a specific gravity of 2.71

Combustion properties: It non-inflammable.

Chemical properties: It dissolves in acids.

Affinity to water: Calcite has the ability to adsorb and absorb moisture. However, it has very poor solubility in pure water. In groundwater or rainwater, it can either be dissolved or precipitated depending on several factors including the water temperature, pH, and dissolved ion concentrations. For example, ambient carbon dioxide, due to its acidity, has a slight solubilizing effect on calcite. It exhibits an unusual characteristic called retrograde=solubility in which it becomes less soluble in water as the temperature increases. In any case, whether dissolved or suspended, calcite has high dispersibility in water.

Affinity to oil: It has low oil absorption capacity.

Heat properties:

- Thermal conductivity: 5.526 to 4.646W/(m K) at 273 K

- Specific heat capacity: 0.203 cal/(g K) at 273 K

- Thermal expansion coefficient: 25.8 x 10-6/K to -4.7 x 10-6/K

- Melting point: 1612 K: Decomposition: 850 °C

Electric properties: It is poor conductor of electricity.

APPLICATIONS

Since calcite is a naturally occurring mineral, it is subject to considerable variation. Its industrial application depends upon properties such as composition, particle size and shape, specific gravity, hardness, and color.

CALCITE IN PAPER

In the paper sector, micronized calcite has been used in paper and cardboard production by adding it into cellulose in different proportions. Since calcite increases the whiteness of paper, naturally grinded calcite is preferred where costs of making pulp are high since it diminishes the requirement of additional whitening pigments. This also makes the process more eco-friendly.

Moreover, calcite keeps less water and increases amount of drawn water thereby increasing production speeds.

Personal Health and Food Production:-

Calcium carbonate is used widely as an effective dietary calcium supplement, antacid, phosphate binder, or base material for medicinal tablets. It also is found on many grocery store shelves in products suchas baking powder, toothpaste, dry-mix dessert mixes, dough, and wine. Calcium carbonate is the active ingredient in agricultural lime, and is used in animal feed. Calcium carbonate also benefits the environment through water and waste treatment.

CALCITE IN PAINT

CALCITE POWDER IS OFTEN USED AS FILLER IN THE MANUFACTURE OF PAINTS, PARTICULARLY WATER BASED PAINTS LIKE DISTEMPER.

- It provides greater covering strength with minimum dripping on the surfaces.

- It has high whiteness which avoids interference with the paint’s colour and contributes to their opacity.

- It is low in cost and further reduces cost of paint manufacture as its high whiteness decreases the requirement of the white pigment titanium dioxide.

- It is also used as an extender in paints.

It is also very useful in powder coatings particularly due to its high dispersibility. Galaxy Global is able to supply calcite powder of very high whiteness. Our calcite imparts excellent hiding properties to the paint. It is very pure containing minimum iron oxide, which would otherwise impart an unattractive hue to the paint. Our calcite disperses well in water and has very low oil absorption. We are also able to offer calcite of different grades so as to optimally suit the customer’s budget.

CALCITE IN PLASTIC

Calcite is used as filler in the production of all major synthetic polymers that make plastic namely polypropylene, polyethylene, polyvinyl chloride, polystyrene, ethylene vinyl acetate. These polymers have various applications like in bags, pipes, automotive parts, furniture, containers etc. Calcite powder is widely used in plastics due to the following benefits: Cost effectiveness: Being a low cost material that can be used in high proportions, it considerably reduces the cost of plastic manufacture.

High whiteness: Calcite’s high whiteness and opacity make it an excellent agent for delustration of naturally transparent man-made fibers without the need for additional pigments like titanium oxide. This ensures that the plastic components exhibit high color intensities and whiteness.

High chemical purity: Calcite is devoid of heavy metal contamination, which leads to aging of the polymers.

High dispersibility: Its grains do not collect together. Rather, they get distributed Low oil absorption: This ensures that minimum resin is absorbed by the filler and also ensures that viscosity of the mix is not affected.

High impact resistance: Calcite’s hardness and strength offer significant resistance to the plastic components against mechanical impact.

Excellent dimensional stability: Calcite’s low coefficient of thermal expansion ensures minimum changes in size upon temperature changes.Moisture absorption: The moisture absorption properties of calcite are useful in order to obtain

high humidity retention, to improve the consistency and dryness of the final mass. Galaxy Global is a reputed supplier of exceedingly pure and high whiteness calcite powder that can be grinded to super fine grain size. Our calcite possesses all the above mentioned characteristics. Its high dispersibility is obvious upon pouring the powder. Since Rajasthan has access to highly

crystalline calcite, its strength and hardness are inevitable. All the important parameters are tested in a well-equipped laboratory so as to ensure quality supply of calcite powder to our customers.

CALCITE IN COSMETIC

- Calcite is widely used in the cosmetics industry in make-up, soaps, toothpastes etc. Use of calcite imparts many benefits in making cosmetic products.

- It has high whiteness due to which it interferes minimally with the color shade.

- Its high opacity offers excellent color intensity to the product.

- It is low in cost. Further, due to its high whiteness, it minimizes the requirement of whitening pigments like titanium oxide thereby significantly reducing the cost.

- It has very good moisture absorption thereby protecting the product from perspiration.

- It is hard and therefore exhibits abrasive properties which are very useful in making soaps, toothpastes etc. Moreover, it alters neither the physical and chemical properties of soap products, nor the viscosity of the mix. Galaxy Global is known for supplying high whiteness calcite. We have access to highly crystalline calcite due to which are calcite grains are hard and compact, possessing good moisture absorption properties and is also very high in purity and thus perfectly safe for bodily applications.

CALCITE IN GLASS

Calcite is a very useful mineral in the glass industry since CaO performs the role of network modifier in glass manufacture. Ca2+ ions interfere with the network of the glass forming oxides like SiO2. Since the network gets disturbed, the melting point and viscosity of the glass forming oxide decreases.

Further, depending upon the concentration and composition of the network modifiers (normally a combination is of different modifiers are used), one can alter glass transition temperature, density,

rigidity, durability and dimension stability. Calcite powder for glass industry must compose of a high and consistent percentage of CaO and be devoid of color imparting impurities like Fe2O3etc. Rajasthan is an excellent source of high whiteness calcite. Galaxy Global offers premium grade calcite powder taking due care of purity and consistency which is crucial for the glass industry to maintain uniformity in structure, color (rather, lack of color) and diaphaneity. Following are the details of Galaxy Global’s glass grade calcite. These specifications are approved by ISI and are subject to modifications as per customer requirement.

CALCITE IN CERAMICS

CALCITE IS AN IMPORTANT INGREDIENT REQUIRED IN THE CERAMIC INDUSTRY

- It acts as a flux, thereby promoting glass formation (vitrification) in the body as well as the glaze by reducing the melting point of the glass former.

- Increases mechanical strength and elasticity of the product.

- It decreases porosity of the product.

- Decreases contraction of the material during the sintering process. Galaxy Global is a supplier of calcite powder that exhibits high whiteness is perfectly suited in composition to meet the needs of the ceramic industry. Our calcite is used in every kind of ceramic product manufactured including art ware, porcelain, pottery, floor tiles, sanitary ware to name a few.

CALCITE IN RUBBER

Calcite is one of the most widely used fillers in non-black rubber manufacture. It imparts the following benefits in rubber making.

- It is a low cost material which can be used at very high loading with little loss of compound softness, elongation or resilience thereby significantly reducing the cost of rubber manufacture.

- It can be powdered to an extremely fine size, which is critical in the rubber industry to provide the desired mechanical properties to it. With suitable surface modifications, it exhibits high dispersibility in the rubber matrix as well has molecular interactions with the rubber matrix. Thus it behaves as an excellent rubber reinforcing agent.

- It has high whiteness, which is important to maintain the desired color characteristics of nonblack rubber. Galaxy Global boasts of extremely high whiteness calcite. In fact, the whiteness can go up to 99%. Moreover, we are able to achieve super fine grain sizes, which is critical for imparting the right mechanical properties to the rubber product.

CALCITE IN ADHESIVES

Most sealants and many adhesives include a ground calcium carbonate (calcite) in the formulation as a filler to reduce costs and increase the solids level. It adds viscosity, contributes to opacity, oil absorption and whiteness and improves mechanical properties like sagging resistance and rheology.

Galaaxy Global is known for its high whiteness and low oil absorption calcite powder of low particle size that is able to pack properly within the adhesive which ensure that it sticks effectively on the substrate

Specification

PRODUCT | CALCITE POWDER |

Rates in INR Per Tonne | 1200 - 3150 |

Particle Size | 100 to 1250 mesh |

Whiteness | Upto 90% |

Brightness | 90 % and Above |

Calcium Carbonate as CaCo3 | 85 - 97% |

Silica as SiO2 | 1.5% to 2.5% |

Magnesium Carbonate as MgCo3 | 1% Max |

Ferrous Oxide as Fe2O3 | 0.1% Max |

Magnesium Oxide as MgO | 1.5% to 2.5% |

CaCl2 | 3.34 g/cm³ |

Other Oxides | 0.20% |

IUPAC Name | Calcium Oxide or Burnt Lime |

Molecular Formula | CaCo3 |

Molecular Weight | 56.0774 g/mol |

Grade Standard | Industrial Grade |

Appearance/Color | White and grey |

State | Powder |

Specific Gravity | 2.7 |

Melting Point | 2,572 °C |

Moisture | 0.20% |

Bulk Density | From 0.40 to 1.2 gms/lt. As per particle size |

Oil absorption value | (22-25/g/100gm) |

PubChem CID | 14778 |

Water Absorption | 40 – 45 ml/100gm |

Lumps | Available |