Calcium Carbonate F4

Product Details:

Calcium Carbonate F4 Price And Quantity

- 900.00 - 7500.00 INR/Ton

- 3 Ton

Calcium Carbonate F4 Trade Information

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- 100 Ton Per Month

- 1 Week

- All India

Product Description

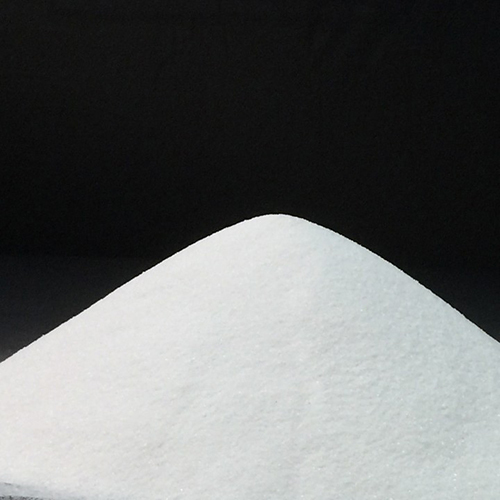

We are proud to reckon as one of the topmost Ground calcium carbonate Exporters from India. We offer finest quality Calcium Carbonate Powder that is known for its purity, whiteness and free flowing nature. Used in various applications such as in rigid PVC pipes, pain, ink, powder coating and ceramic industry. Good dispersion properties of Natural Calcium Carbonate Powder make it widely recommended by our esteemed customers. In addition to this, Calcium Carbonate Powder is also available in different quantities and packing as per the requirements of patrons. Natural Calcium Carbonate Powder can be obtained at the most competent prices.

Typical Properties of Calcite :

- Higher flow properties

- Higher mechanical properties in thermoplastic applications

- Better gloss and whiteness in Paints & Powder coating applications

- Excellent dispersion properties

- Prevents chalking

- Better corrosion resistance

Application of Calcite :

- Leather Cloth Industry

- Paints, Inks, Powder Coating & Ceramic Industry

- Rubber Industry

- As a flux in Glass Industry & in sizing of Textile goods

- Our grades of Calcite powder are available in 300 Mesh to 700 Mesh BSS standard & in

- Micronize grades, Our grades are available in top cut 5, 10, 15 & 20 Microns.

Chemical Composition Of Calcite :

- CaCO3 90% to 97%

- MgO 1.5% to 2.5%

- Silica 1 % to 3.5%

- Variation of the specifications stated due to natural raw materials & environment

- conditions are possible. though they have no influence on the application properties described.

Surface Treated Calcite

We also do coating on Calcite powder. We provide coating of Steric Acid. The Coated Calcium Carbonate powder is used in plastic compounds manufacturing to avoid moisture contains. Coating is done from 1% to 3% or as per customer requirement.

Typical Properties of Surface Treated Calcite :

- Rapid and complete dispersion

- Low abrasion at higher loading

- Low moisture content

- Good compatibility with Polymers & other additives

- Increased flow rate

- Reduced plasticizers & other additives

- Better HDT

- Better Impact strength

- Better dispersion

- Lower raw material cost

Application Of Calcium Carbonate

Personal Health and Food Production:- Calcium carbonate is used widely as an effective dietary calcium supplement, antacid, phosphate binder, or base material for medicinal tablets. It also is found on many grocery store shelves in products such as baking powder, toothpaste, dry-mix dessert mixes, dough, and wine. Calcium carbonate is the active ingredient in agricultural lime, and is used in animal feed. Calcium carbonate also benefits the environment through water and waste treatment.

Building Materials and Construction:- Calcium carbonate is critical to the construction industry, both as a building material in its own right (e.g. marble), and as an ingredient of cement. It contributes to the making of mortar used in bonding bricks, concrete blocks, stones, roofing shingles, rubber compounds, and tiles. Calcium carbonate decomposes to form carbon dioxide and lime, an important material in making steel, glass, and paper. Because of its antacid properties, calcium carbonate is used in industrial settings to neutralize acidic conditions in both soil and water.

Specification

| PRODUCT | GROUNDED CALCIUM CARBONATE POWDER |

| Rates in INR Per Tonne | 4600 To 7400 |

| Particle Size | 20 Microns To 2 Microns |

| State | Powder |

| Whiteness | 92-95% |

| Brightness | 93% Min |

| Purity | 75% / 85% / 95% |

| Calcium Carbonate as CaCo3 | 75% - 95% |

| Silica as SiO2 | 1 - 3.5% |

| Magnesium Carbonate as MgCo3 | 0.4% - 3% |

| Alumunium Oxide as Al2O3 | 0.1-0.5 |

| Sodium Oxide as Na2O | < 0.05 |

| Sulphate as SO4 | 0.02 % Max |

| Chloride as Cl | Traces |

| Iron (Fe) | < 100 ppm |

| Calcium oxide as CaO | 1.5% to 2.5% |

| Magnesium Oxide as MgO | 1.5% to 2.5% |

| CaCl2 | 0.6 to 0.8 |

| Appearance/Color | White |

| IUPAC Name | Calcium carbonate |

| Other Name | Calcite |

| Molecular Weight | 100.0869 g/mol |

| Molecular Formula | CaCO3 |

| Grade Standard | Industrial Grade |

| pH Value | 8.5 to 8.8 |

| Refractive index | 1.59 |

| Specific Gravity | 2.5 - 2.7 |

| Melting Point | 1,339 C |

| Boiling point | Decomposes |

| Loss on ignition | 43% - 44% |

| Loss of Drying | 0.4 Max |

| Lumps | Available |

| Solubility | Max 1% |

| Bulk Density | 0.9-1.35 |

| Oil absorption value | 40 to 50% |

| Fe, Al,PO4 Matter Insoluble | Max. 0.5% |

| Soluble Alkali as Na20 | Max. 0.2% |

| Acid Insoluble | Soluble |

| Volatile Matter | Min 96% |

| Solubility in water | 0.0013 g/100 mL (25°C) |

| Density | 2.711 g/cm3 (calcite), 2.83 g/cm3 (aragonite) |

| Odor | Odorless |